Definition and importance of 5'S & KAIZEN(LEAN MANUFACTURING TOOLS)

5S and Kaizen are related in the fact that they are both concepts used in Lean manufacturing and both have the goal to improve processes and reduce wastes and are both derived from Japanese concepts. While 5S and Kaizen have the same end goal, they introduce different strategies to achieve that goal and certain situations will benefit from Kaizen while other scenarios will call for the organization strategies of

5S.

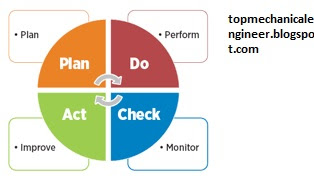

When looking to improve or change processes, the

methodology of Kaizen will be much more helpful to managers and employees. Both

daily Kaizen and Kaizen events work to break down processes into smaller

processes or tasks to identify smaller improvements that can be made. Kaizen

helps employees learn how to complete their tasks in the most effective way and

then how to standardize practices so everyone in the workplace can take

advantage of the improved process.

5S works to improve processes through organizational means. Having a work bench or workspace that is organized in a logical way is an excellent foundation for the rest of the facility to operate smoothly. 5S offers a series of steps a manager or employee can through to organize the space. These are 5 steps all beginning with ‘S’ and are: sort, straighten, shine, standardize, and sustain.

It will be important for managers and supervisors to

evaluate the problems or issues at hand and whether 5S or Kaizen should be

implemented as a solution. 5S and Kaizen can be implemented either separately

and at different times or a facility can choose to use both strategies around

the workplace. Another option is to implement the strategies at separate times.

For instance, to get the most benefits from a Kaizen event, it can help if the

space is organized so it is easier to identify possible issues. Whichever one

you may choose for your facility; it is key to take the time to implement them

correctly and train employees on their participation.

Thanks for visiting

If you want to learn more regarding industrial knowledge please visit on below link

1 टिप्पणियाँ

america

जवाब देंहटाएं